Understanding Different Types of Trailer Brakes

Towing a trailer comes with great responsibility, and one of the most critical aspects of safe towing is the braking system. Understanding the different types of trailer brakes and how they function ensures smoother, safer travels.

Here’s a comprehensive guide to the types of trailer braking systems available, their components, and why they matter.

Types of Trailer Brakes Chart

Trailer Drum Brakes vs. Disc Brakes

Before we get into the three types of brakes found on many trailers today, it’s important to know the difference between drum brakes and disc brakes. Trailers can have either of these types, and either can be used on electric, surge, or hydraulic systems.

Trailer drum brakes are made up of a drum and brake shoes. Upon activation, the shoes within the drum are pressed outward, causing friction between the two surfaces and slowing the rotation of the drum and ultimately the trailer wheel.

Trailer disc brakes are comprised of a disc or rotor and brake pads. This type of brake also uses friction, but instead of the pads being housed inside, they sandwich the rotor. Once the brakes are activated, the pads squeeze together, pushing against the rotor and slowing its rotation.

1. Electric Brakes

Electric brakes are among the most popular options for modern trailers due to their precision, reliability, and ease of use. As the name indicates, electric brakes operate using electricity.

Just like on your car, electric trailer brakes can come with discs and pads or drums and shoes. However, instead of the being actuated by pressure from brake fluid from your foot on the pedal, electric brakes are actuated by electricity.

How Electric Trailer Brakes Work

Electric trailer brakes operate via electric signals sent from the tow vehicle, namely, the brake controller within the tow vehicle. When the driver presses the brake pedal, it signals the brake controller, which sends an electrical signal to the trailer. An electromagnet inside the trailer brake assembly activates, causing the brake shoes or pads to engage the drum or rotor.

How Brake Controllers Work

Benefits of Electric Brakes

Electric brakes offer several advantages that make them a popular choice for trailer owners. One of their key features is adjustability, allowing drivers to fine-tune the braking force to match the load weight and road conditions. This is done using the brake controller, and the trailer brakes themselves can also be adjusted. This ensures optimal performance and safety, whether towing a light utility trailer or a heavily loaded RV.

Another benefit is their compatibility with a wide range of trailers, including recreational vehicles, utility trailers, cargo trailers, horse trailers, and more. This versatility makes electric brakes a go-to solution for many towing applications, accommodating different types of trailers with ease.

In addition to their adaptability, electric trailer brakes are known for their ease of maintenance. Compared to other braking systems, they require less frequent adjustments, saving time and effort while ensuring consistent and reliable operation. This combination of features makes electric brakes a practical and dependable choice for trailer braking systems.

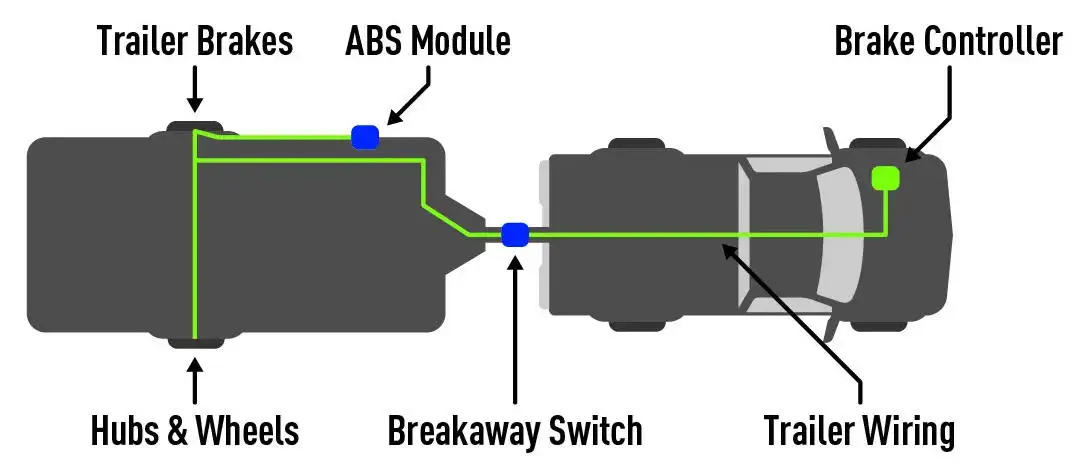

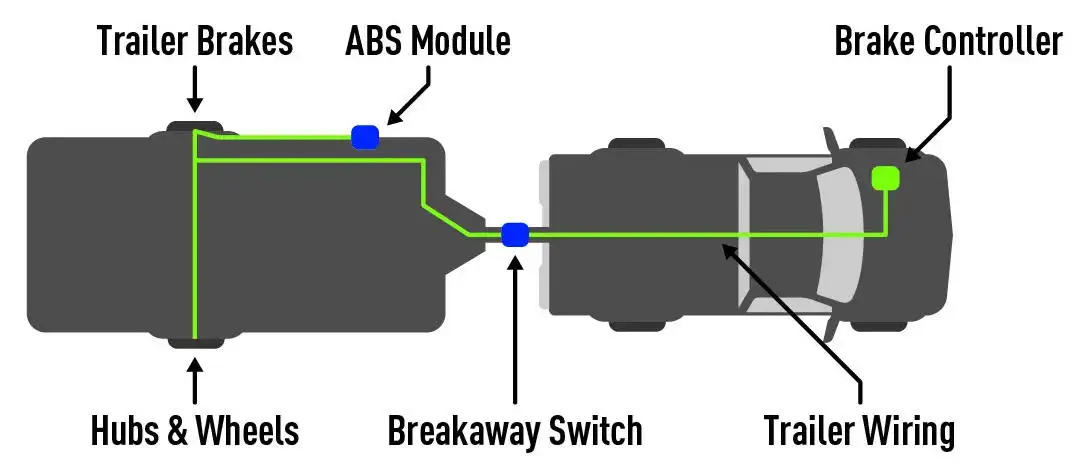

Electric Trailer Brake Components Explained

Each electric braking system on a trailer relies on key components working together. Many of these parts are also used on surge brakes and hydraulic braking systems, but some, such as the trailer brake controller, are unique to electric systems.

Trailer Brakes

The trailer brakes are the parts that apply the immediate stopping pressure to the trailer wheels to decelerate the vehicle. On trailer drum brakes, these parts include the shoes, drums, and other components. On trailer disc brakes, they include the brake pads and rotors.

Trailer Hubs & Wheels

The wheels on a trailer and especially the hubs are also essential parts of the braking system. The trailer hub is the housing for the braking components, such as the drums and shoes. The hubs also provide the structure on which the trailer wheels rotate, and the wheels serve as the direct contact point between the trailer and the road, allowing the trailer to decelerate.

Brake Controller

Typically located inside the tow vehicle, the trailer brake controller regulates the braking force applied to the trailer. The two primary types include time-delay controllers and proportional controllers, offering varying levels of control and responsiveness. A brake controller also usually provides some kind of interface to allow the driver to monitor braking activity.

Trailer Wiring

There are many different forms of trailer wiring and many functions that it can carry out. Trailer wiring is essential for electric trailer brake operation. Dedicated trailer wires facilitate communication between the tow vehicle and the trailer's brakes – when to apply stopping power and when not to. Proper wiring is crucial for electric and emergency brake systems.

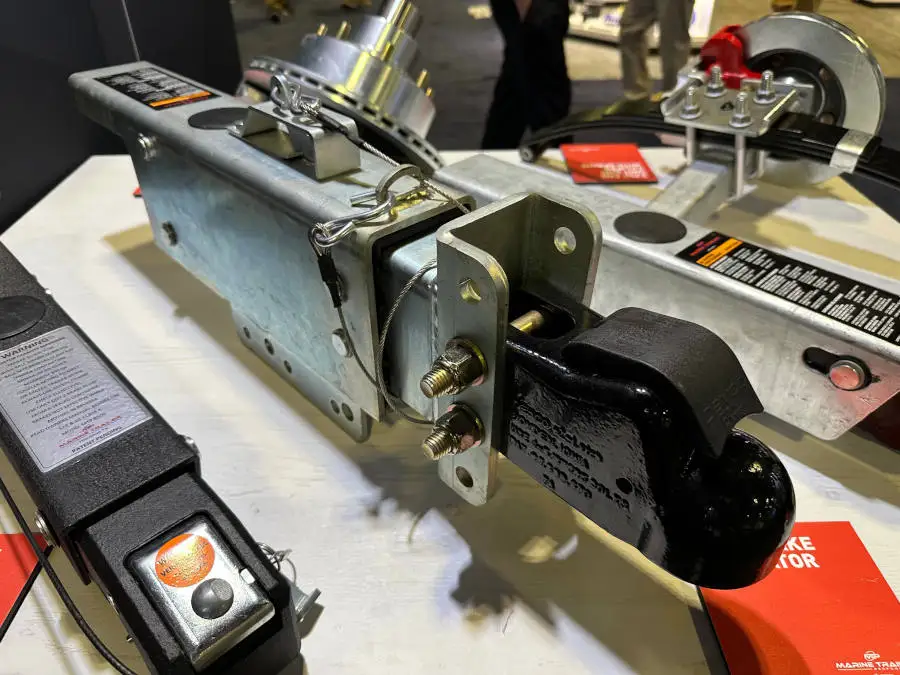

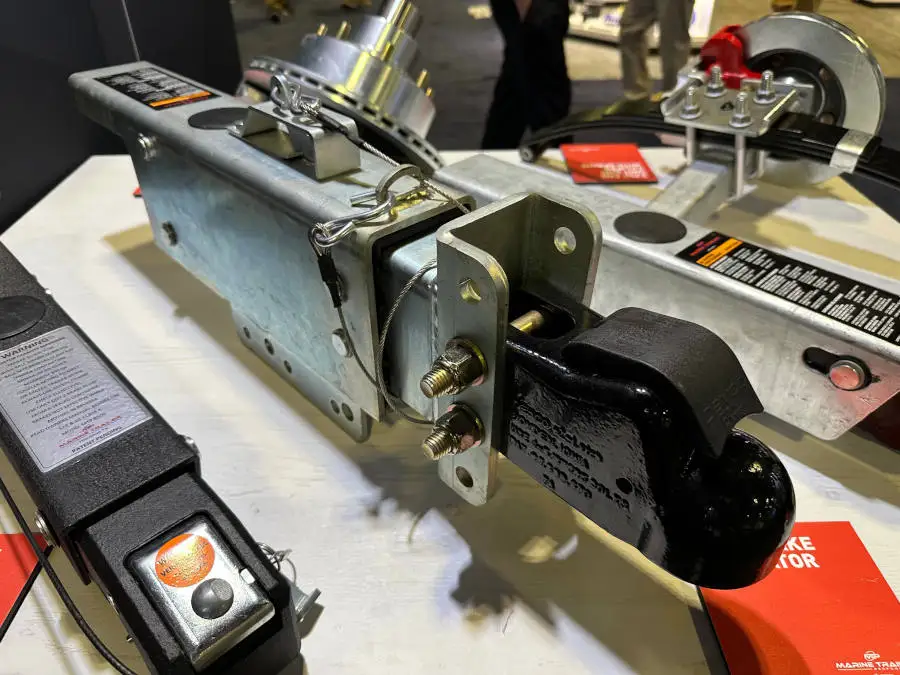

Breakaway Switch & Battery

The breakaway system, comprised of a switch and special dedicated battery mounted on the trailer, activates the trailer brakes in the event of an unintended vehicle detachment. A breakaway system is not required on every trailer, but some do require it, particularly if that trailer is large enough to have electric brakes.

ABS Module

Advanced trailers may feature anti-lock braking systems, such as the Lippert ABS system, which prevent wheel lockup and enhance control in slippery or emergency situations.

2. Surge Brakes

Trailer surge brakes are a simple, self-contained braking system that doesn’t rely on electrical connections. Surge brakes are popular on boat trailers and operate based on the principles of physical force and momentum. Just like electric trailer brakes, surge brakes are designed to assist the tow vehicle in stopping the trailer.

How Surge Brakes Work

Surge brakes use the momentum of the trailer to apply stopping power to the wheels. Imagine the amount of force that’s pressed against the vehicle’s hitch and rearend as you apply the brake pedal. The idea behind surge brakes is to capture this force and turn it into brake actuation. When the trailer pushes against the tow vehicle during deceleration, a hydraulic actuator compresses, creating pressure in the brake lines that engages the brake shoes or pads in the trailer wheels.

Perhaps their greatest advantage is that surge brakes don’t require a brake controller. They’re a completely self-contained system. The hydraulic actuator is typically part of the trailer’s tongue, and no electrical signals are needed for telling the brakes when to activate.

Which Trailers Use Surge Brakes?

Surge brakes are particularly advantageous for boat trailers and other marine trailers, where water exposure can make electrical components unreliable. Their design eliminates the need for electrical connections, making them a durable and dependable option in aquatic environments.

Surge brakes are also an excellent choice for trailers without an electrical system, providing a straightforward and self-contained braking solution. Without relying on external power, trailer surge brakes operate efficiently using the momentum of the trailer itself, offering a hassle-free setup for owners seeking simplicity.

Favored for their simplicity and effectiveness, this type of braking system performs well, even in wet or challenging conditions. The hydraulic actuation ensures smooth and controlled braking, making them a reliable choice for various towing needs.

3. Hydraulic Trailer Brakes

Hydraulic brakes provide powerful and precise braking, and they are often used in heavy-duty towing applications. Hydraulic brakes are not unlike the brakes in most cars, trucks, and other automotive vehicles. Hydraulic brakes in trailers can operate using the physical momentum of the trailer (as in surge brakes like we just described) or using electricity.

How Hydraulic Brakes Work

Hydraulic trailer brakes rely on hydraulic fluid to actuate the brake shoes or pads. This fluid must be placed under pressure to then travel through the brake lines to the brake assemblies. This pressure can be created by an electrically operated master cylinder or by the momentum of the trailer itself.

Benefits of Hydraulic Brakes

Hydraulic brakes offer several key benefits, making them an excellent choice for trailers carrying heavy loads. They provide superior control, ensuring stability and safety even in challenging towing conditions. Known for their smooth and responsive braking performance, hydraulic brakes deliver precise stopping power that is especially valuable for trailers carrying significant weight.

To maintain their effectiveness and safety, proper upkeep is essential, including regular checks of brake fluid levels and inspection of brake components. With diligent maintenance, hydraulic brakes remain a reliable and efficient braking solution.

What Does Electric-over-Hydraulic Mean?

Electric-over-hydraulic trailer brakes are a hybrid braking system that combines electric brake control with hydraulic actuation. This system is commonly used in trailers that require the power and responsiveness of hydraulic brakes but want to retain the adjustibility and control offered by an electric brake controller.

Here's how it works:

The electric component of the system begins when the driver in the tow vehicle applies the brake pedal. The brake controller in the vehicle sends an electrical signal to the trailer's brake system. Instead of directly activating the trailer’s brakes with electricity, the electric signal is used to control a hydraulic actuator on the trailer. The actuator converts the electrical signal into hydraulic pressure, which then engages the trailer's brakes, typically using hydraulic drum brakes or disc brakes.

What about Air Brakes?

Typically found in commercial and large-scale trailers, air brake systems offer unparalleled braking power. Compressed air stored in the towing vehicle’s reservoirs powers the brake chambers, which convert air pressure into mechanical force to engage the brakes.

Air brake systems provide precise control over braking force, offering enhanced safety when towing heavy loads over long distances. This makes them particularly valuable for commercial applications, such as freight trailers and heavy-duty RVs. Air brakes are designed to handle the demands of large trailers, where robust braking capabilities are a necessity. Their ability to deliver consistent and powerful braking performance ensures stability and control, even under the heaviest of loads. For trailers that require superior braking power, air brake systems are an essential feature to ensure safe and efficient towing.

Do Trailers Come with Emergency Brakes?

Many trailers come with an emergency braking system, called a trailer breakaway system. Emergency trailer brakes, or a breakaway system, is an essential safety feature designed to activate if the trailer detaches from the tow vehicle.

How a Trailer Breakaway System Works

Breakaway systems operate using something called a breakaway switch, as well as a trailer-mounted backup battery. The switch is designed with a small cable that connects between the trailer and the tow vehicle.

If an unintended separation occurs, the breakaway switch triggers the trailer brakes to activate. This action is powered by the backup battery, which sends electrical power to the brakes. This separate battery is used to ensure functionality even if the trailer loses electrical connection.

Legal Requirement for Emergency Brakes

In many regions, emergency brakes are required for trailers exceeding a specific weight limit. They also provide critical peace of mind and added safety for your trip. If you’re unsure if your trailer requires emergency brakes in your region, consult your local authorities.

Disclaimers: These photographs, recommendations, and approximations are intended for demonstration purposes only and do not reflect the specifications of any particular tow vehicle, recreational vehicle, or trailer. Always consult the manufacturer’s Owner's Manual.

ARIES

ARIES  CURT

CURT  LUVERNE

LUVERNE  UWS

UWS